tuotteen yksityiskohdat

Swing welding head

The process that traditional magnetic head cannot complete, the swing welding head only needs to use 70% of the power, which can save the cost of the laser.

In addition, the swing welding method, the width of the solder joint is adjustable, and the depth of fusion is strong, which makes up for the small shortcomings of the laser solder joint.

The tolerance range and weld width of the processed parts are enlarged, and a better weld forming effect is obtained.

Brand laser generator

IPG, JPT, MAX, Raycus laser generator optional.

Laser power: 1000W , 1500W , 2000W

Simple operating panel

Display operation interface, simple and eye-catching button, no programming and teaching, simple operation

Machines Features

Helppo käyttää

Simple and easy to operate, no deformation of the welding seam, stable laser output to ensure welding consistency, high power density after laser focusing, fast speed, great depth and small deformation, 360-degree micro-welding.

Fast welding speed

Kaunis hitsausprosessi

Alkuperäisen työpöydän rajoitukset rikkoen se soveltuu kaikenlaisiin monimutkaisiin hitsaussaumoihin ja se on helppo hitsata mikä tahansa työkappaleen osa mistä tahansa kulmasta. Humanisoidulla suunnittelu- ja teknologiapäivityksellä voidaan hitsata kauniita hitsaussaumoja.

Pieni runko, tehokas hitsaus

The welding speed of JNKEVO laser welding machine is 3-10 times that of traditional argon arc welding and plasma welding. The welding heat affected area is small, and it will not cause problems such as deformation, blackening, traces on the back of the joint construction, and the welding depth is large, the melting is sufficient, and the welding is firm.

Kaksikäyttöinen kädessä pidettävä kääntölaserhitsauspää

On 6 hitsaustilaa ja useita hitsaussuuttimia erilaisiin hitsaustarpeisiin; siinä on turvaanturitoiminto, joka lähettää laserin kosketuksen jälkeen metalliin ja lukitsee valon automaattisesti, kun se poistetaan; spiraalivärintätoiminto, hitsin leveyttä voidaan säätää ja hitsauskyky paranee merkittävästi.

360° Ei kuollutta kulmamikrohitsausta

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned, and is applied to micro and small workpieces that are automatically produced in large quantities. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, stitch welding, tailor welding, sealing welding, etc. High aspect ratio, small weldwidth, small heat aff

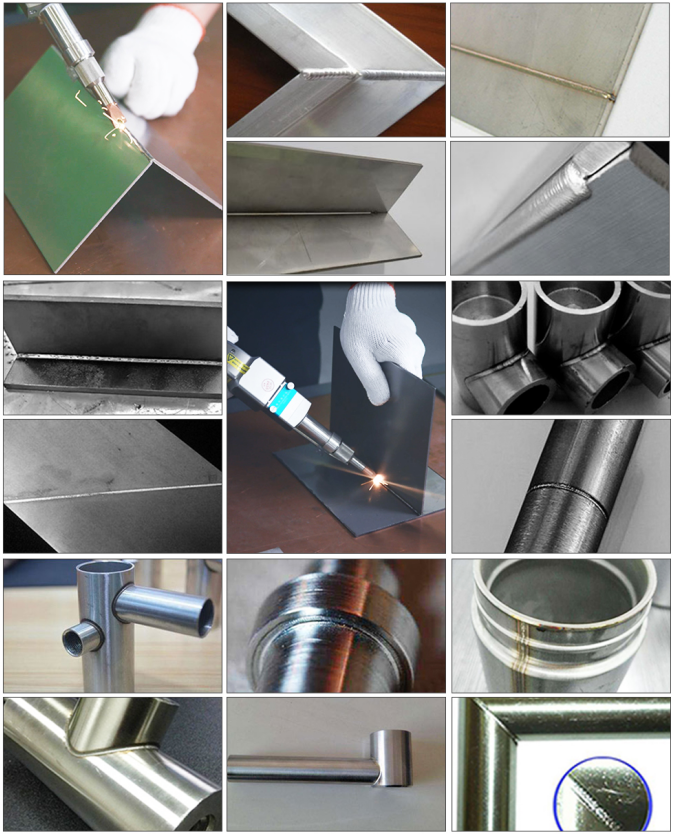

Sovellus