Sovellus

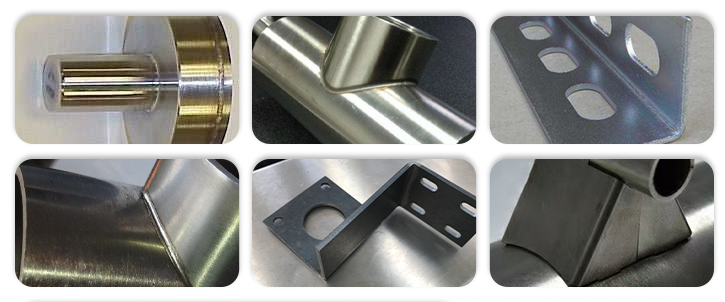

Laser welding is a new welding method, which is widely used in precision processing industries such as automobile industry, metal processing industry, ship and aircraft manufacturing, Furniture and kitchenware processing, electronic products processing, metal parts maintenance, etc. It is mainly aimed at the welding of thin-walled materials and precision parts. It can realize spot welding, butt welding, overlap welding and seal welding. Laser welding machines for titanium alloy, galvanized sheet, aluminum material and copper material can accurately weld

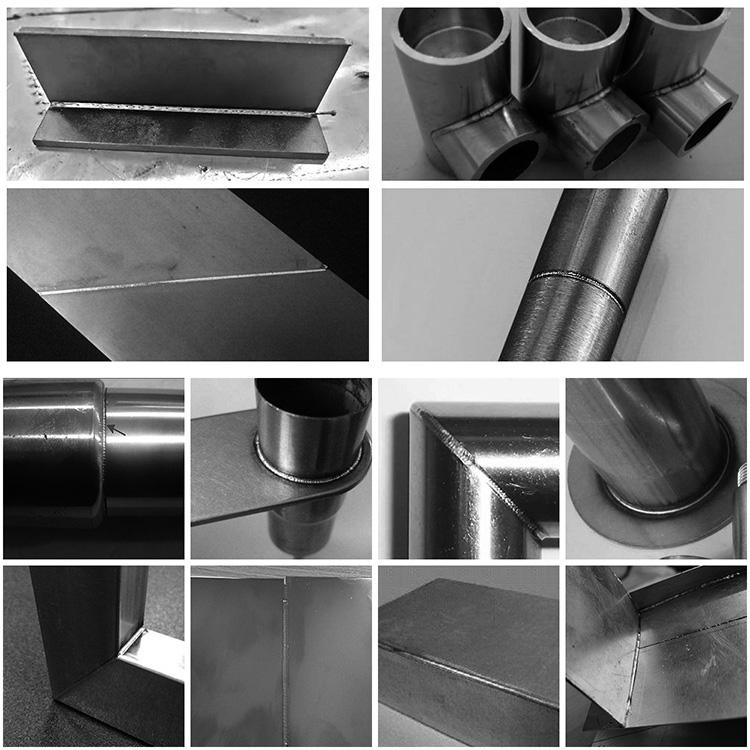

Right angle welding sample Tube Arc welding Irregular seam welding

Advantages of laser welding

1. It can weld some other components that are easy to be damaged or cracked during welding without contact and will not cause mechanical stress to the welding object

2. It can irradiate the narrow parts that cannot be accessed by the soldering iron head on the circuit with dense components and change the angle when there is no distance between adjacent components in dense assembly, without heating the whole circuit board

3. During welding, only the welded area is heated locally, and other non welded areas are not subject to thermal effect

4. The welding time is short, the efficiency is high, and the solder joint will not form a thick intermetallic layer, so the quality is reliable

5. High maintainability. The traditional electric soldering iron welding needs to replace the soldering iron head regularly, while the laser welding needs to replace very few accessories, so the maintenance cost can be reduced

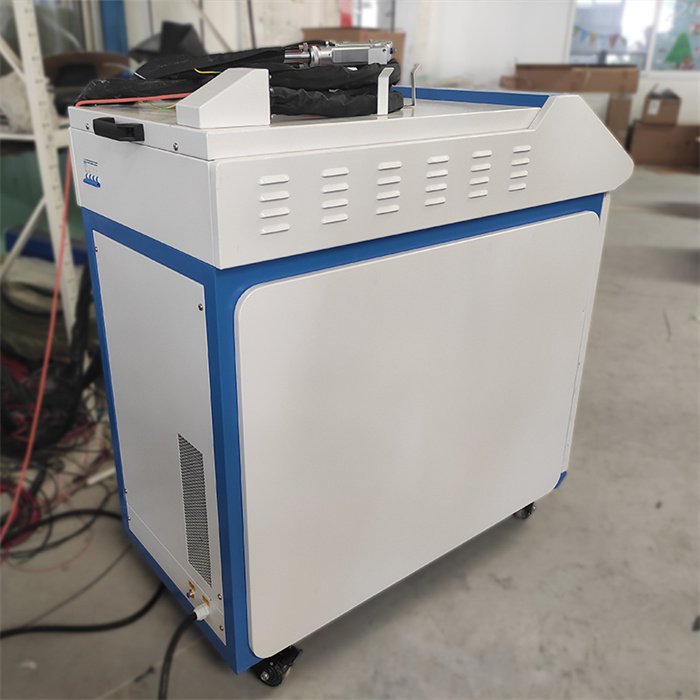

Kokoonpano

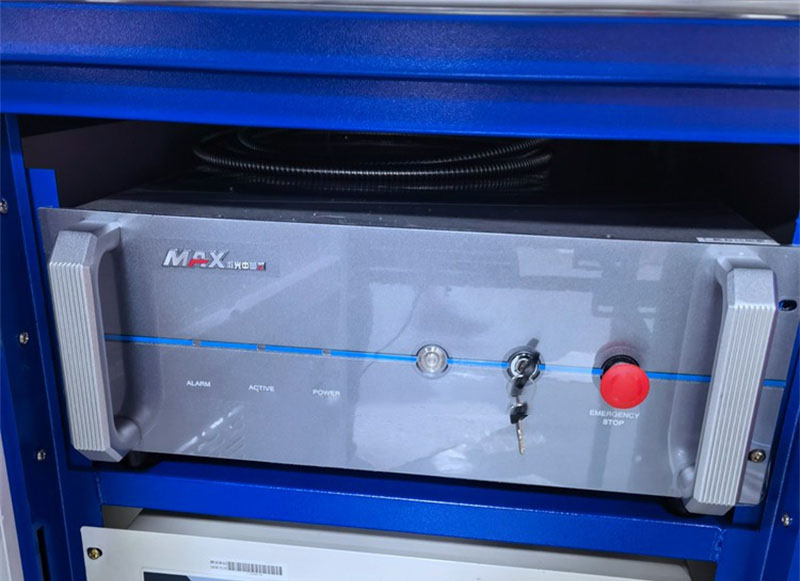

HW welding head HW control system Auto wire feeder for free

WSX/JPT optional usually coperate with laser head

Laser power Water chiller Comes with a variety of nozzles

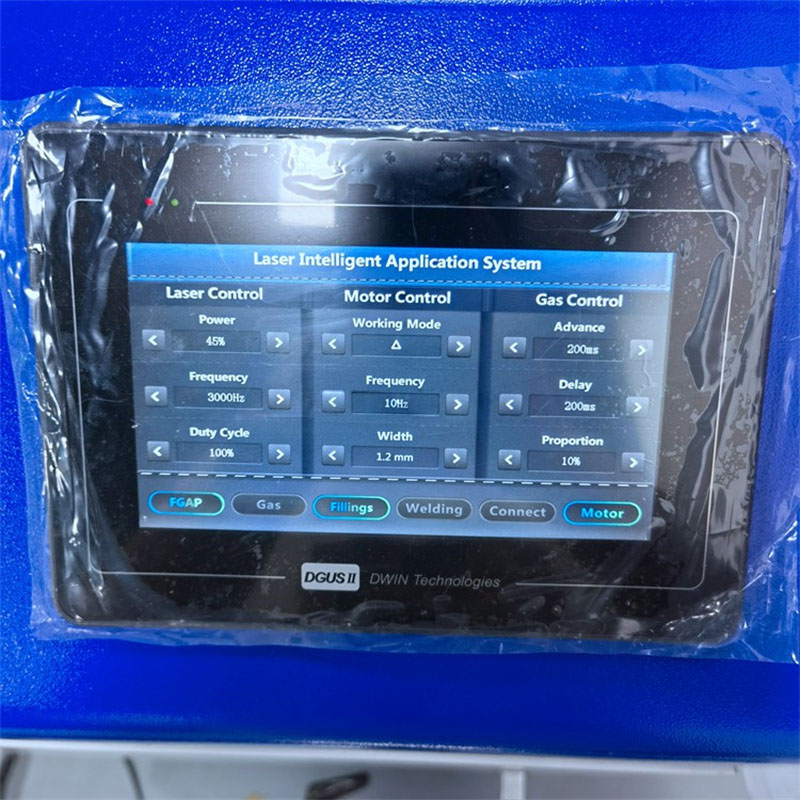

Parametrit

Malli | LXW-1000/1500/2000W |

Laserteho | 1000/1500/2000W |

Keskiaallonpituus | 1070+-5nm |

Lasertaajuus | 50Hz-5KHz |

Työkuviot | Jatkuva |

Sähkön kysyntä | AC220V |

Lähtö kuidun pituus | 5/10/15 m (valinnainen) |

Jäähdytysmenetelmä | Vesijäähdytys |

Mitat | 1150*760*1370mm |

Paino | 275kg (noin) |

Jäähdytysveden lämpötila | 5-45 ℃ |

Keskimääräinen kulutettu teho | 2500/2800/3500/4000W |

Laserenergian vakaus | <2 % |

Ilman kosteus | 10-90% |